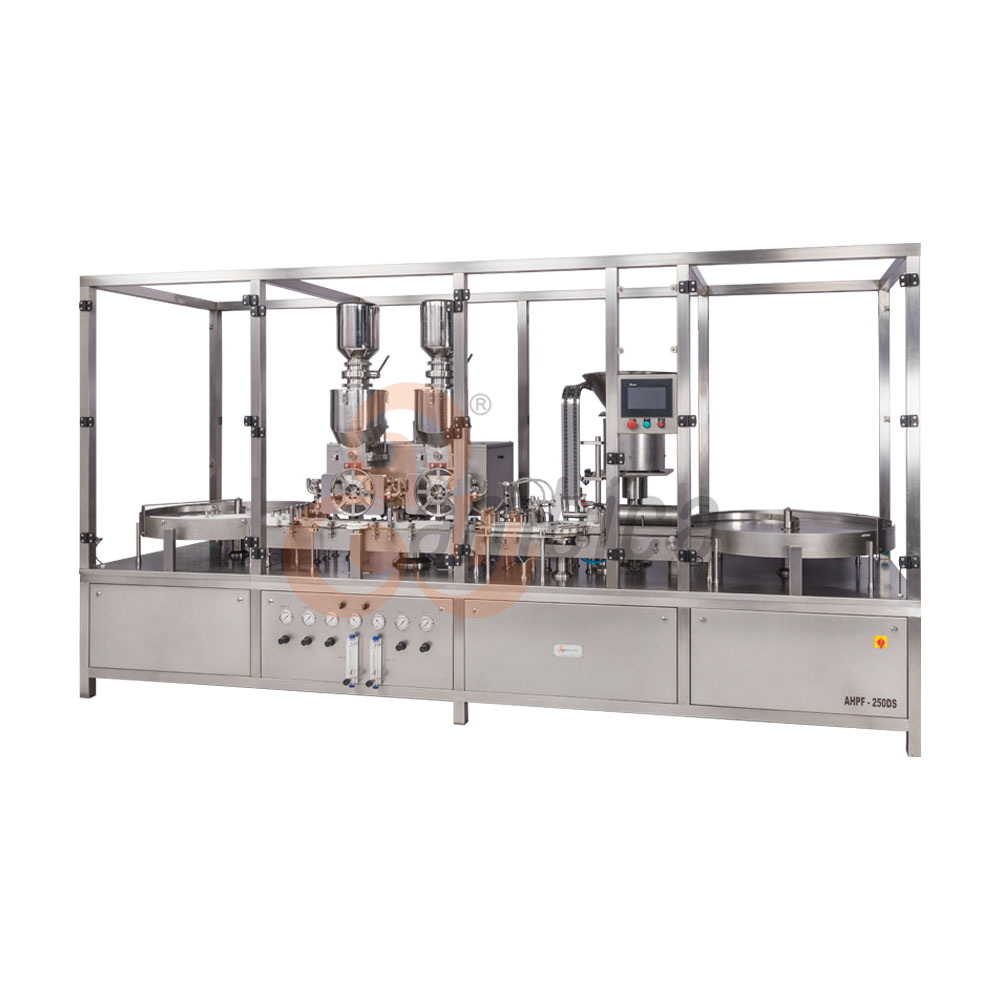

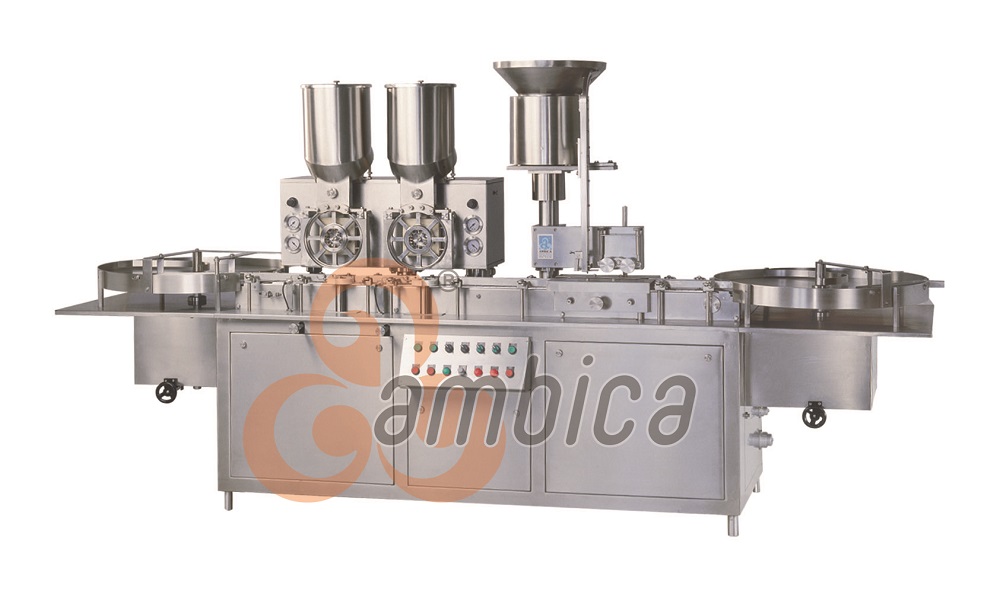

Automatic High Speed Injectable Dry Powder Filling with Rubber Stoppering Machines. Models: AHPF-120 & AHPF-250D

Automatic High Speed Injectable Dry Powder Filling with Rubber Stoppering Machines. Models: AHPF-120 & AHPF-250D

Automatic High Speed Injectable Dry Powder Filling with Rubber Stoppering Machine is completely mechanical driven machine with self picking roller based rubber stoppering system. This machine has a very sturdy design and can withstand long working hours. Filling is done with help of vacuum and air pressure based powder wheel with manual fill weight setting.

Product Details

Technical Specifications

7,200 Fills for Single Dose

3,600 Fills for Double Dose

2,400 Fills for Triple Dose

1,800 Fills for Four Dose

50 mg to 1.5 gm In single dose with help of extra change parts and 1.5 gm to 5 gm by double, triple and four dose depending upon bulk density of powder

5 ml to 30 ml

20 mm

3250 mm (L) X 1050 mm (W) X 2100 mm (H) (Approx.)

14,400 Fills for Single Dose

7,200 Fills for Double Dose

4,800 Fills for Triple Dose

3,600 Fills for Four Dose

50 mg to 1.5 gm In single dose with help of extra change parts and 1.5 gm to 5 gm by double, triple and four dose depending upon bulk density of powder

5 ml to 30 ml

20 mm

4000 mm (L) X 1350 mm (W) X 2100 mm (H) (Approx.)

Salient Features

- All contact parts are easily removable for autoclaving / sterilization

- All the parts coming in contact with powder are made of S.S 316L

- Online pre - media filling system

- Pre & post gassing system

- Multiple dosing system with the help of change parts

- Individual drives for infeed and outfeed turntable

- A/C frequency drive for speed control

- Pure air filters for air and vacuum

- Safety clutch system to avoid vial breakage

- Machine equipped with high quality gear box (Make: Rotomotive)

Optional Accessories

- Powder loading system above hopper

- Laminar air flow system

- PLC with touch screen HMI with interlocks & alarms indication